|

The new fattening barn in prefabricated design in Lower Bavaria on the Austrian border under the management of Schauer Pocking.

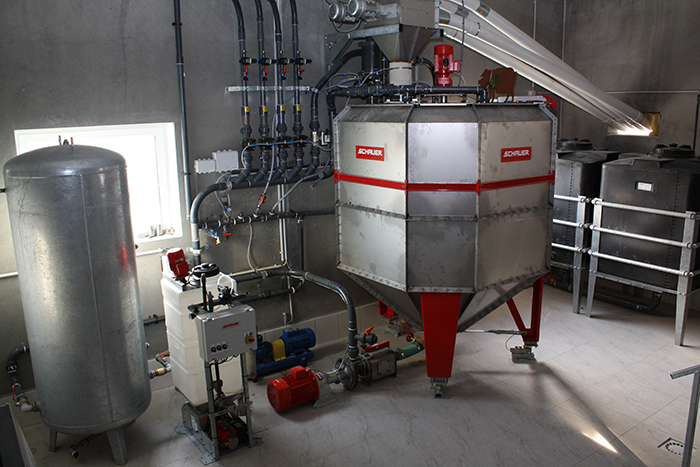

Leonard Brauneis senior and junior (father and son) are experienced and successful pig farmers near Bad Füssing in Lower Bavaria, where they previously had approximately 2,000 fattening places in the village area. Once extending the farm was no longer possible, the decision was taken to construct a fattening barn 800m away on a green meadow. Mr. Alfred Putz, a specialist consultant from the company Schauer in Pocking, accompanied and supported the Brauneis family from the start, from obtaining the planning permission and operational approval of the commercial fattening barn to the completion of the construction work and handover for the start of production.  No compromises with the quality – short construction time – prefabricated barn from Farmbau and Schauer  Liquid feeding with the Easy Diamond mixing tank – provides every department with the correct recipe The construction work started in November 2013. The first animals entered their stables at the beginning of April. The Brauneis family kept a keen eye on the construction costs from the very start. With the costs including the development and approval costs totalling € 500.- excl. VAT per fattening place, the target value was only just missed slightly. Several expert surveys were necessary to obtain the approval regarding emissions regulations from the regional council. In the end, with the professional planning of the ventilation system, it proved possible to provide the basis for positive permission. The hall was constructed on a prefabricated basis with the company Farmbau. The 10cm core-insulated concrete walls have a total height of 420cm. This enables a slurry pit with a depth of 100cm and a clear room height under the porous ventilation ceiling of 280cm. The hall was set up in the shortest time and saves a considerable amount of work as the smooth walls are ready for use without any subsequent work. For the ventilation during the summer, supply air cooling is provided via front-mounted coolpads which are not yet installed, however. In the summer, the supply air is drawn from the attic with controlled ceiling valves via the passage and into the sections; in the winter, via porous ceilings which are arranged in the edges of the sections. The exhaust air is withdrawn via individual drawing systems with chimneys 3m above the roof. The fattening barn consists of 4 open sections with 498 pig fattening places. As the feeding system, a Liquimix liquid feeding system from Schauer was installed with the new Easy Diamond mixing tank. Vitaplus also provides the needs-based and removal-free medication to the pigs as required. The feeding concept is simple but highly efficient. Adapted to each day, every section is provided with its own recipe several times a day via the sensor short trough feeding. The livestock feeding place ratio is 2.6:1. The feed line to the four sections is configured as a one-way line. This also enables the removal-free medication of the livestock since the mix of medication is consistently dosed in the correct concentration during the feeding. At the end of the fattening, the feed lines are blown out and cleaned with compressed air and water. The new Topo moisture-proof computer highlights the high level of functionality and user friendliness with high-quality design.  Leonard Brauneis (father and son) places his trust in the collaboration with Alfred Putz from Schauer Agrotronic Since the operation for the newly created fattening places is no longer able to access the feed basis sufficiently, contrary to the widespread use of CCM in the region, this was not used, and instead, additional silos with a total storage capacity of 290m3 were set up in order to mix the individual feed components with dried maize, wheat, barely, soya as well as raw fibre and mineral without direct premixing with the liquid feeding system. This enabled clear savings in feed costs. The Brauneis family is satisfied with the reliable collaboration it has experienced with the team from Schauer in Pocking. As the barn is now occupied, holding an open day is no longer possible. For those who are interested, however, site visits are possible in compliance with the hygiene regulations upon enquiry with Schauer in Pocking. We would like to wish the Brauneis family every success with their new prefabricated fattening barn from Schauer and Farmbau. |

| Schauer Agrotronic - GmbH - A-4731 Prambachkirchen - Passauerstrasse 1 - +43 7277/2326-0 - www.schauer-agrotronic.com Impressum . Kontakt |